| Mask Fabrication |

| - Mask Dimensions |

| - Fabrication Process |

| - How to Order |

| Silicon Microfabrication |

| - Capabilities |

| - Facilities |

| One-Stop Services |

Processing Capabilities

Our capabilities include most processes needed to fabricate a microelectromechanical system, from process development to chip fabrication. Single process capabilities, such as photolithography, thin films deposition, wet and dry etching or metrology services are also available.

Microlithography

Microlithography

Lithography by Mask Aligner/Stepper

E-beam Lithography

Laser Lithography

Thin Film Deposition

PECVD for deposition of SiO2 and SiN thin films

LPCVD for deposition of Si oxide, Si nitride and poly-Si.

RF/DC sputter for depositing thin metal layers

UBM sputter for deposition of oxide and doped TCO films

E-Beam evaporation system for deposition of metals

Thermal evaporation system for deposition of organic layers

Dry Etching

Dry Etching

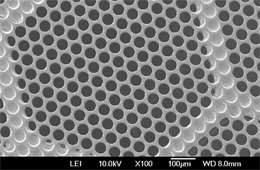

Silicon Deep Etching

Etching of SiO2/Si3N4

Photoresist Stripping

Surface Treatment of Si/Glass

Etching of III-V based compound materials

Wet Etching

Bulk Silicon Micromachining

Etching of SiO2

Etching of Metals

Liftoff of Metals

Metrology/Characterization

Surface profiling

Elipsometer

Back-end processing

Dicing of Si, Quartz, Glass, III-V material

Wire bonding

Trimming of substrates, drilling of holes, surface treatment of polymeric materials