| Mask Fabrication |

| - Mask Dimensions |

| - Fabrication Process |

| - How to Order |

| Silicon Microfabrication |

| - Capabilities |

| - Facilities |

| One-Stop Services |

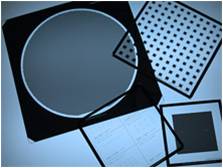

Mask Fabrication

Lithographic photomasks are typically transparent glass templates covered with chrome patterns. They are designed to optically transfer patterns to wafers or other substrates in microfabrication.

Lithographic photomasks are typically transparent glass templates covered with chrome patterns. They are designed to optically transfer patterns to wafers or other substrates in microfabrication.

Depending on the difference of the substrates, BondaTek fabricates three types of photomasks: quartz masks, soda lime masks and mylar masks. The attainable critical dimensions (CD, i.e. minimum feature sizes) for these three types of masks are 0.75, 1.5, and 25 micrometers, respectively. Typical mask dimensions are 3"x3", 4"x4", 5"x5", 6"x6" and 7"x7". These photomasks are either direct-written by e-beam or laser systems or are manufactured from reticles using photo repeater systems.

Tighter specifications, larger mask sizes and other types of masks are also available upon request. Contact us for more information about our capabilities.