| Mask Fabrication |

| - Mask Dimensions |

| - Fabrication Process |

| - How to Order |

| Silicon Microfabrication |

| - Capabilities |

| - Facilities |

| One-Stop Services |

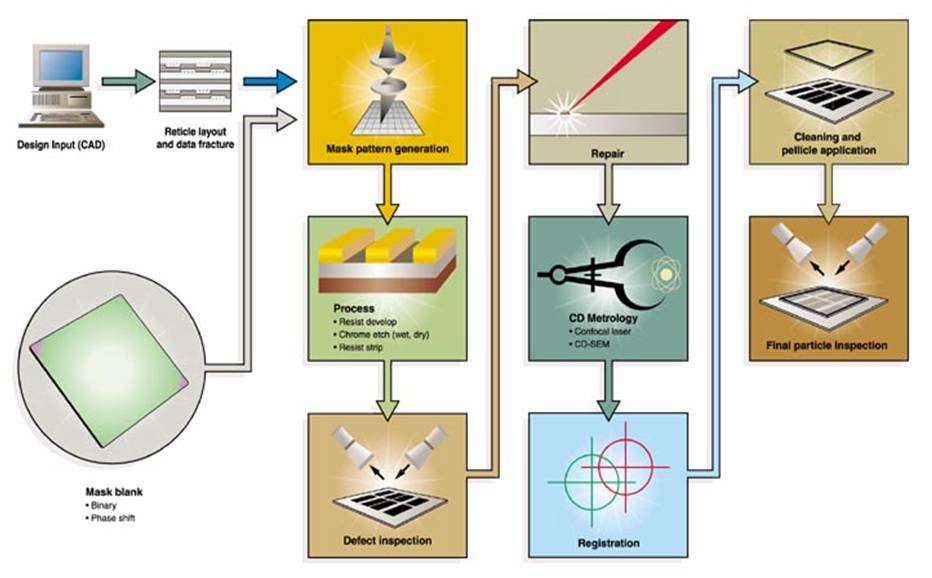

Fabrication Process

Originally the pattern information is created in a drawing package and stored in a database, reformatted and transferred to a lithography tool � laser writer (ALTA3900) or e-beam writer (MEBES5500/5000) in our case � then printed in a layer of photoresist coated onto the photomask blanks.

The imaged pattern is next developed to form a template over the opaque chrome and then the chrome is etched away where the resist is clear. After the etch process is complete, the remaining photoresist is removed, the plate cleaned, and then stored for later use in an optical printer.